Helping to make old things new again…

Did you know that chlor-alkali chemistry helps us to recycle things more efficiently?

At its very heart, the production of chlor-alkali centres around the sustainable use of chemicals.

When the chlor-alkali production process was invented in the 19th century, alkali (or lye) was being made for use in ’novel’ chemicals like soap. As part of this, ‘wastes’ such as hydrogen and chlorine were also produced. These were of obvious value and as such industries developed in order to use these wastes. This resulted in the industry as we know it today and the improvement of our modern lifestyles.

As part of the modern production of chlor-alkali, chemical 're-use' remains important. For example the brine (the source of the chlorine) is re-used to reduce the amount of raw materials needed. In addition, in some chlor-alkali plants, any hydrogen produced can be used to generate steam for on-site heating to improve energy efficiency. This hydrogen may one day also have other uses as an energy source in our communities.

Chlor-alkali products enabling a more circular future for everyone...

One of the key chlor-alkali products is sodium hydroxide. This important chemical is found in many different end products but is also helping to recycle other products to contribute to a more sustainable planet.

For example, sodium hydroxide regenerates many of the chemicals used in the pulping of wood chips for paper production. This means that the pulp mill can reuse more of the production chemicals. Sodium hydroxide is also used is in paper recycling. Here, it controls the pH of the chopped-up paper and also helps the old paper fibers to swell. This helps to separate any ink printed on the paper, allowing the fibers to be reused.

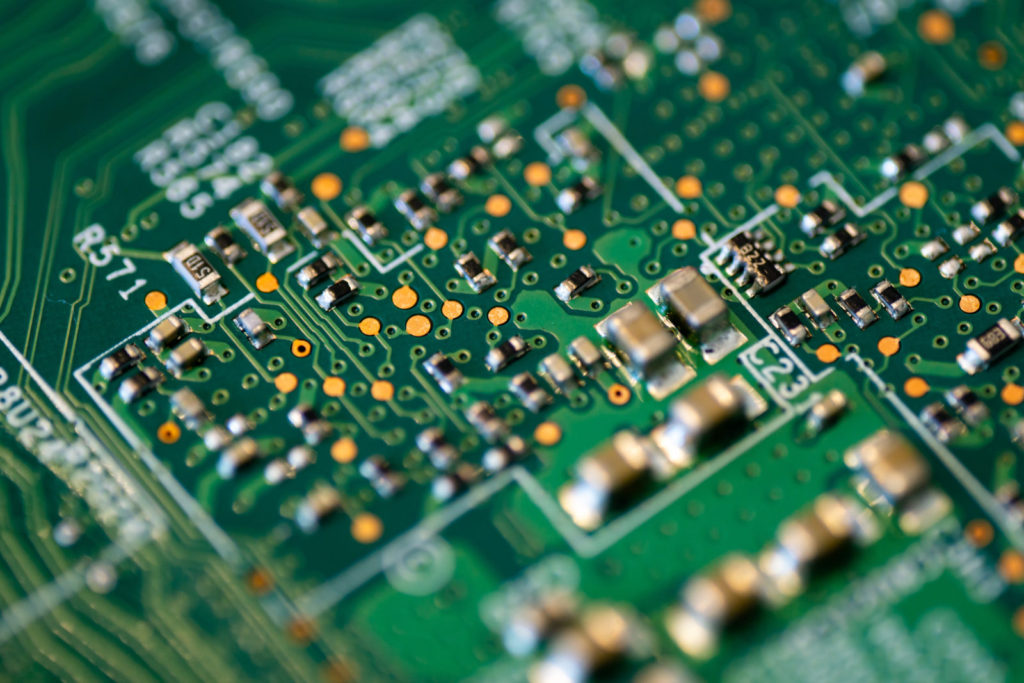

Sodium hydroxide is also helping to recycle old microchips and circuit boards in electronic devices. It removes the coatings on the boards to make them easier to dismantle and re-use. This important chemical also helps in the recovery of metals such as gold, copper, zinc and platinum from these old circuit boards. Some companies can even carefully use sodium hydroxide to clean and purify recycled gold jewellery!

Finally, sodium hydroxide is also used to purify recycled bottles to make sure they are safe to be re-used as drink containers.

Other important chlor-alkali chemicals are the chlorinated solvents. These are used in modern dry-cleaning and metal cleaning machines. These solvents are easily recycled inside these machines as an essential part of the cleaning cycle. This recycling significantly increases the eco-efficiency of the chlorinated solvent. Used solvents are then externally recycled for re-use, whilst the residues (dirt, grease etc.) are safely collected and disposed of by experts. This all takes place within a closed system to limit exposure to the handlers and the environment.

Saving releases of CO2 via chlor-alkali chemistry...

One final key chlor-alkali product is PVC or polyvinyl chloride. This is a very familiar material used for pipes, cables, window frames, credit cards and much more. PVC itself is actually very easy to recycle. Indeed, one group is currently recycling almost 800,000T per year, cutting down on the waste disposal requirements. VinylPlus estimate that for each kg of PVC recycled, 2 kg of CO2 are saved. On this basis, PVC recycling in Europe is now saving around 1.5 million tonnes of CO2 per year.

Chlor-alkali chemistry is contributing to a more sustainable future for Europe.